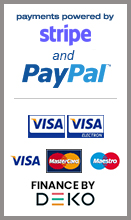

Schluter BEKOTEC-EN12FK Studded Screed Panel With Anchoring Fleece

Studded Screed Pane

With Anchoring Fleece On The Underside

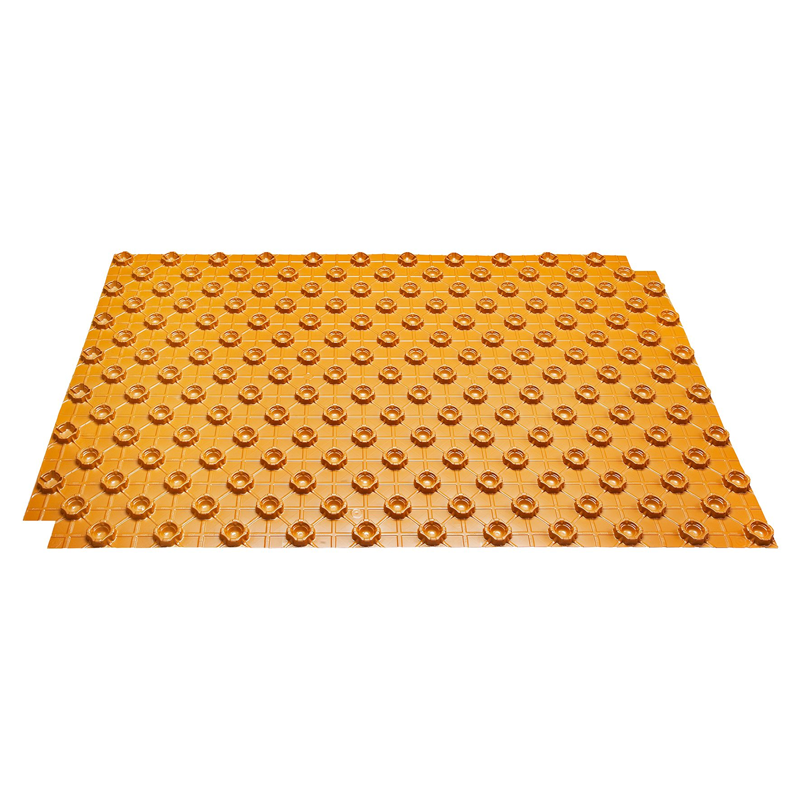

Supports Pipe Diameter: 10mm

Size: 1.15m x 75cm

Coverage: 0.77m²

Schlüter-BEKOTEC-EN 12 FK is a reliable covering assembly system for crack-free and functionally safe floating screeds and heated screeds with coverings made of ceramic tiles, natural stone, and other materials.

The floating system is installed directly on load-bearing, weight-distributing substrates such as concrete or existing wooden floor structures, using the thin-bed method. The thin-bed screed must be manufacturer recommended for the corresponding substrate. The suitability of the substrate for heating purposes (movement joints, edge strips etc.) must be verified. The system is based on the studded polystyrene screed panel Schlüter-BEKOTEC-EN 12 FK with an anchoring fleece on the underside. The studded screed panel is directly installed onto suitable weight-distributing substrates as a bonded assembly, using the thin-bed method. The geometry of the studded panel Schlüter-BEKOTEC-EN 12 FK results in a minimum screed thickness of 20 mm between the studs and 8 mm above them. The studs are designed to hold the heating pipes of the system (diameter: 10 mm) in a grid pattern of 50 mm in order to create heated screeds.

The floor heating system is easily adjustable and ideally suited for use with low temperatures since the screed volume to be heated or cooled is relatively small (approx. 40 kg/ m² ≙ 20 l /m² with 8 mm coverage). The curing stresses that occur in the screed due to shrinkage are absorbed by the studded pattern, thus controlling deformations such as curling. It is therefore unnecessary to install dummy joints or movement joints in the screed. As soon as the cement screed is ready to support weight, the uncoupling mat Schlüter-DITRA 25 can be installed (calcium sulfate screed < 2 CM-%). Ceramic or natural stone tiles are then installed directly over this layer, using the thin-bed method. Movement joints in the covering layer are created using Schlüter-DILEX according to industry guidelines. Cover materials that are not susceptible to cracking, such as parquet or carpeting, can be directly installed over the screed as soon as it reaches the necessary residual moisture level for the corresponding covering. See the Technical Manual for further details.

Stud Diameter: Approx. 44mm.

Installation Spacing: 50, 100, 150mm etc.

Diameter Of System Heating Pipes: 10mm (The studs have a cutback design to securely keep heating pipes in place without the need for clamps.)

Connections: The studded panels are connected by overlapping a row of studs and clicking the panels together.

Working Area: 1.1 x 0.7 m = 0.77m².

Panel Height: 12mm.

.jpg)

.jpg)